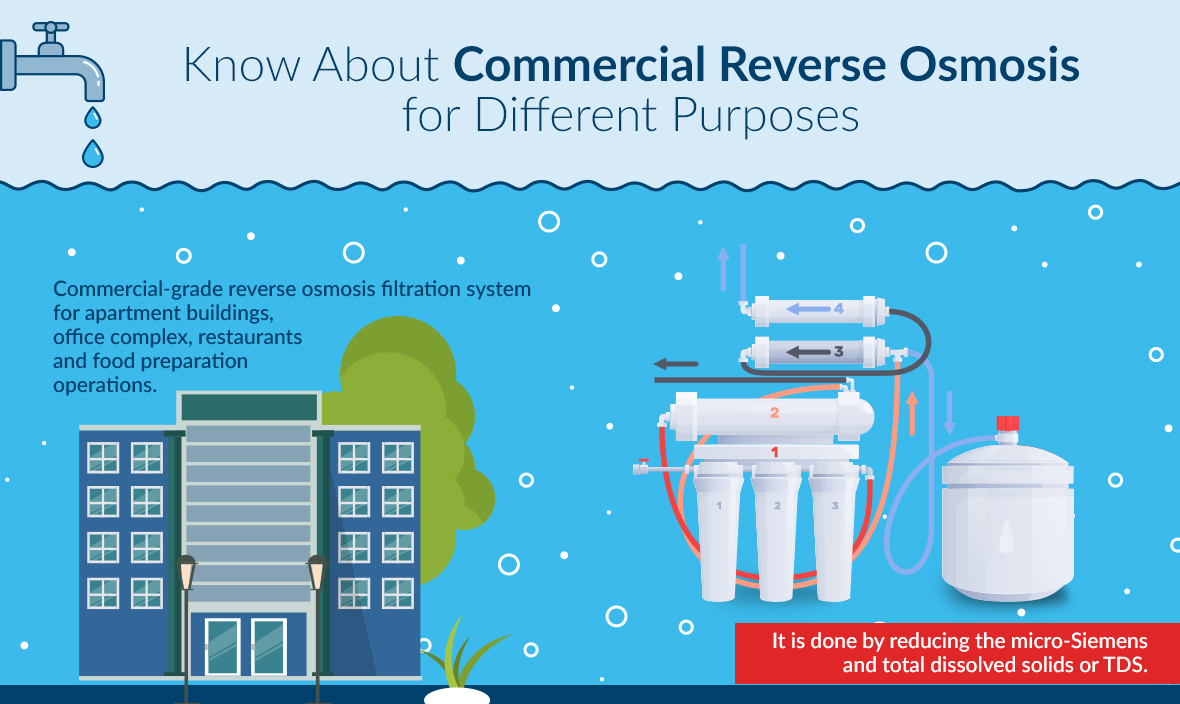

Reverse Osmosis systems work on the basis of water that passes through a system to remove impurities. The water comes into the system through a tank or mains feed; the quality of the incoming water may differ with geographic location. A high-pressure pump is used – driving the water through a set of membranes – counted as a selective barrier. As water passes through it, impurities like salt and other contaminants are removed. The process is helpful in improving the purity and quality of the incoming water supply. It is done by reducing the micro-Siemens and total dissolved solids or TDS.

Commercial Reverse Osmosis Systems for Beer Making

Commercial RO systems are larger and bigger in size in comparison to those, used in homes for pure and filtered water. The working process is the same for both commercial and residential RO systems. They both use RO membranes to filter the water. They are used to separate water molecules from other dissolved solids in the water like chemicals, heavy metals, carbonates, and a lot more.

Such RO Systems are ideal for the commercial field of beer making – comparatively faster, consume less time, and have a larger storage unit for emergencies too. They are energy efficient and provide you with sufficient pure and well-filtered water to use on beer making or for different other industrial and commercial purposes. These water filtration systems are ideal to reduce the acidic value of water and get ready to use alkaline water for beer categories like stout and drought.

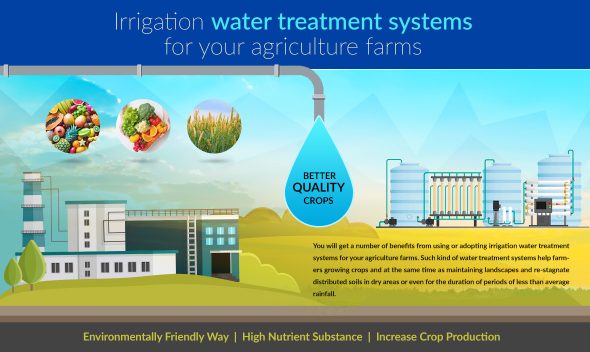

Reverse Osmosis Systems for Agriculture Farms

Reverse Osmosis systems are ideal to use for agriculture purposes for farms as they come with multiple levels of filtration to increase efficiency. The process starts when water passes through a series of filters before reaching the purity level and then being sent to the holding tank.

These systems work in an easy way with water enters the farm water treatment system and goes through a sediment filter to sort out the large solids – mainly keep finer filters protected from any kind of blockage. The process is not till this point as water passes from the second and third filter – after being filtered for large particles and sent to the RO pumps, where the water goes through the special Osmosis filter to help it reach the osmosis membrane to filter on a molecular level. In this way, the filter becomes able to send purified water into a holding tank.

Choose the Best Model of Commercial Reverse Osmosis Systems

Getting quotes directly from the top manufacturers will be an added advantage to choose the best range of commercial reverse osmosis systems. Find the right one of your choice, go through the details, and place your order.

Leave a comment

You must be logged in to post a comment.