Clean Water; It’s what plants crave!

Commercial hydroponic growing operations require consistency to obtain maximum yields and profits.

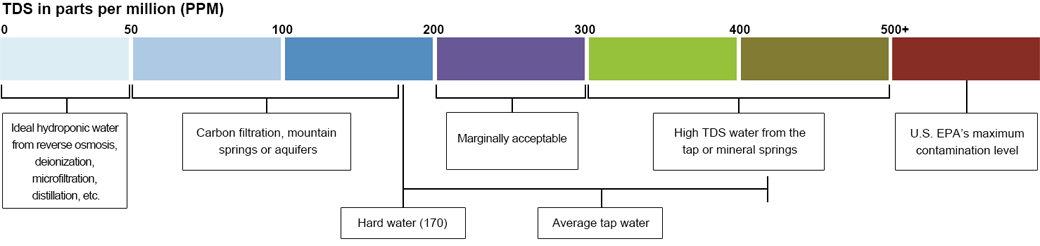

Eliminating variables is one of the key benefits of hydroponic growth or hydroponics water filter. Nutrient formulas have been tailored specifically to each type of plant and crop. One of the most important variables in commercial hydroponic growing is the water used to make and maintain nutrient solutions. When you examine professional nutrient manufacturer’s mixing specifications, you will notice they all require using 0 ppm (parts per million) water as a starting point for the nutrient solution formulation.

Without purified water, it is much more difficult to adjust your formula and make sure you have the proper amounts of each component necessary for healthy growth. Your water source may actually be detrimental to plant growth. Chlorine is a well-known example.

Chlorine in trace amounts in the form of chloride is an essential nutrient for plant metabolism. High levels of chlorine, however, can be toxic to plants. Water treatment plants sometimes shock the water supply with excessive levels of chlorine to treat biological contaminants. These shock treatments are not announced and could end up killing an entire crop. Chloramine is another chlorine-based disinfectant that can harm plants and other types of hydroculture operations. The US Environmental Protection Agency claims that a low level of chloramines in drinking water is safe for plants, but it can be poisonous to fish and compost teas.

Water hardness is a major hydroponic problem found in most municipal and well water supplies. Hard water is caused by an excess amount of calcium and magnesium dissolved in the water. Ironically, calcium and magnesium are the same minerals found in most complete plant nutrient formulations. The problem is the high concentrations cause excessive mineral salt build-up on the roots and in the growing media, leading to nutrient lockout. At the very minimum, the plants won’t be able to uptake the proper balance of the nutrients required for sustained growth. In the worst case, the major nutrients required for growth will be made unavailable which eventually causes the crop to die.

Some water supplies high in carbonates require the addition of acids to lower the pH. If the pH is out of range, nutrients are rendered unavailable for absorption by the plants. When phosphoric acid is added to lower the pH, the bicarbonates are neutralized to carbon dioxide and water. Some of the acids reacts with the calcium to form insoluble calcium phosphate. Calcium phosphate is about 95% water-insoluble and precipitates out of solution as limescale. Once it is precipitated,

the calcium and the phosphate are unavailable to the plants. The calcium phosphate scale will clog up drip irrigation lines and submersible pumps. If the water supply contains high levels of bicarbonates, it could require ten to fifteen times as much phosphoric acid to lower the pH of the nutrient solution. This increases the danger of phosphorus toxicity.

Some water supplies use water sources from several locations, each with different chemical make-up. You never know from one day to the next what your water quality will be like. Sodium levels in excess of 2,000 ppm have been found in some inland water sources.

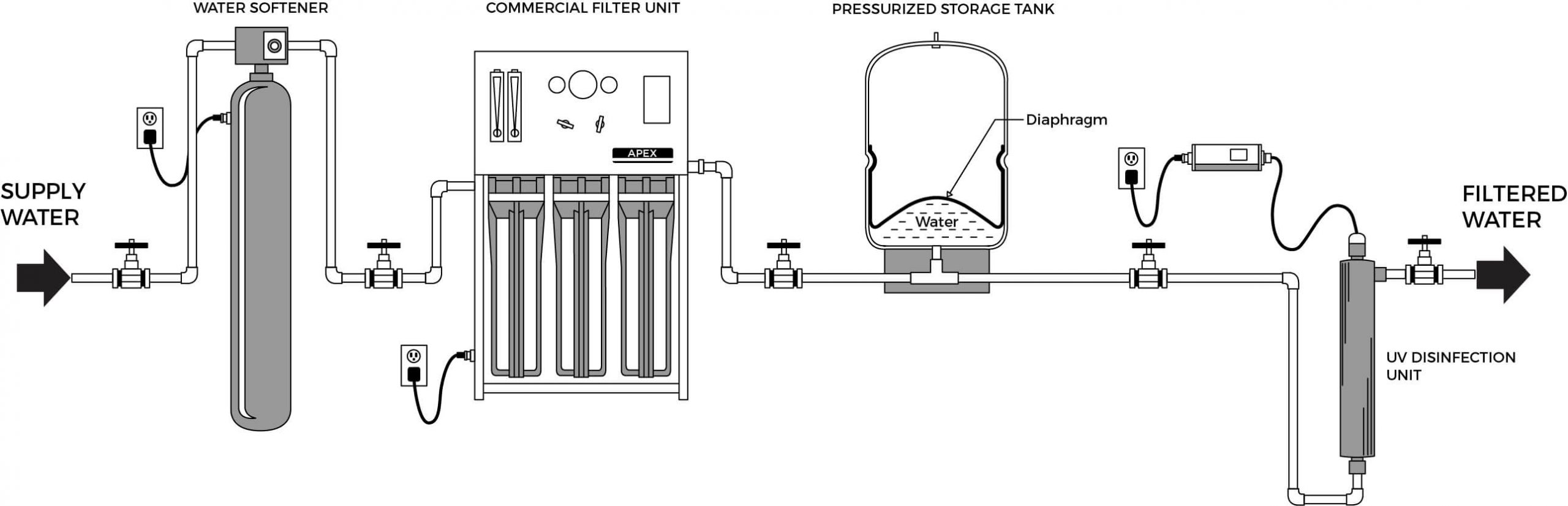

Figure 1.2 Recommended Installation of a Commercial Hydroponic Water Filter System

Sodium can interfere with trace element uptake and cause nutrient deficiency symptoms. Trace elements, such as copper, boron, zinc and iron, can also occur at high levels and lead to toxicity.

The best available technology to remove disinfection chemicals and excess minerals from your water supply is the reverse osmosis (RO) filter system. APEX commercial hydroponic reverse osmosis systems are designed to provide the best water for hydroponic growing operations by hydroponics water filter system.

APEX reverse osmosis systems are complete turn-key water purification systems featuring micron sediment pre-filtration, activated carbon cartridges for removal of chlorine, chloramine and organic pollutants and reverse osmosis filtration that removes all minerals, salts and heavy metals.

Municipal and Well Water Hydroponic Filters

Brackish Water Hydroponic Filters

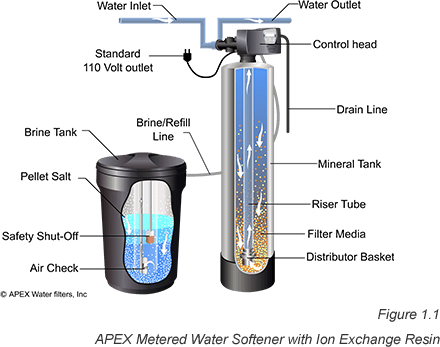

Water Softeners

APEX WS-1060 Metered Water Softener – 64,000 Grain

With an APEX commercial hydroponic filtration system, all of the minerals in your nutrient solution will come from the fertilizers, not from the water supply. In this way, a nearly perfect nutrient balance can be achieved. If you want to achieve maximum growth, yields and profits, stop gambling with your water quality and switch to an APEX commercial hydroponics water purification system or hydroponic reverse osmosis system!

Leave a comment

You must be logged in to post a comment.