Ninety seven percent of the earth’s water can be found in our oceans

Desalination is the process of taking salty or “brackish water” and turning it into drinking water. Countries, municipalities, armed services and ships have to produce freshwater by desalination because it is limited or unavailable. Desalination technology produces freshwater and along with it industrial advancements to areas that otherwise might have remained undeveloped and inhabitable. More importantly, the health and welfare of many people have been improved by a reliable source of purified drinking water. Turning seawater into potable water has several advantages. Seawater is always available since 97% of the water on Earth is brackish. It is a reliable resource with seemingly unlimited supply capabilities. Desalination operations can be established in coastal zones and send the freshwater to distant areas. Desalination is a complex multi-stage process that involves a series of specialized filtration techniques.

The main function of desalination is to remove salts and minerals from the feed water. This can be done with distillation but the energy costs are prohibitive. The best available technology is reverse osmosis (RO) filtration. It all started back in 1969 when sophomore engineering student Dean Spatz discovered that a special semi-permeable membrane could turn brackish water into pure drinking water. That process, using the reverse osmosis membrane, has become the main desalination technology used around the world. As of 2015 there are over 18,000 desalination plants operating in 150 countries throughout the world. More than 300 million people rely on desalination to produce over 22 billion gallons of water a day.

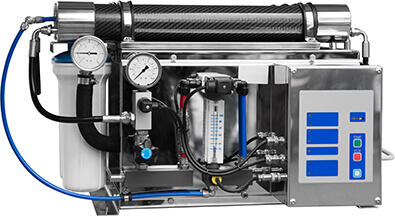

Sea water desalination plant

The Pretreatment Process

Turning seawater into drinking water is much more complicated when compared to processing raw freshwater into potable water fit for consumption. Besides being “salty,” brackish water and seawater are teeming with living, dead, organic and inorganic particulate matter. Every gallon of seawater contains millions of living and dead algae cells, bacteria, and zooplankton. Microscopic analysis also reveals fragments of marine plants, mucus from fish and invertebrates along with sand, carbonate particles and ground up crustacean shells. The latest threat to desalination plants are transparent exoploymers (TEPs). A major contributor to fouling, TEPs are gelatinous colloids (0.4-200 microns). The gels come from the surface of algae, bacteria and other aquatic organisms. The surface of the ocean may contain 3,000 to 40,000 TEPs particles per milliliter of water. TEPs carry bacteria and provide a ready nutritional supply to stimulate biofouling throughout the desalination plant. All of this suspended matter is held in suspension by water movement, swimming motion of plankton and algae, and electrostatic forces (zeta potential). The first stage of the desalination process focuses on removing the suspended solids and colloids from the water. Raw brackish water is agitated with a coagulation agent like ferric sulfate or more advanced polyelectrolyte flocculation chemicals. The idea is to collapse the electrostatic charges that keep the particulate matter in suspension so it falls to the bottom of a settling chamber or raceway. Some coagulants also cause the particles to clump together, forming heavier agglomerations that settle more quickly.

Multi-media Filtration

The water is now filtered through a multi-media chamber containing layers of granular media like course gravel, fine sand, garnet and anthracite. The flow rate is slow to allow capture of the particles. Suspended particles are trapped within the media, much like a large sand filter. The flow rate is specified in gallons per minute in relation to the square feet of filter media. The multi-media filter is backwashed periodically to flush away captured particulates and debris. The brackish water may also go on to a diatomaceous earth process to strain out more particles. Sediment cartridge filters act as the final pretreatment stage. The five-micron filter cartridges capture particles that slip through the coagulation and flocculation process. The number of suspended particles leaving this stage is monitored and must be kept within the system’s operating specifications to prevent clogging of the RO membrane.

High Pressure Pumps

The clarified water is now pumped under high pressure to an array of reverse osmosis filters. The incoming water is forced through the spiral-wound reverse osmosis membranes at high pressure (about 800 psi). The greater the pressure, the higher the rate of fresh water movement through the membranes. There are two types of water pumps used for desalination RO systems: centrifugal and positive displacement pumps. The positive displacement or “plunger pumps” are used most often in the more common 1,000 to 100,000 gpd capacity desalination plants. Positive displacement pumps suffer from variable (pulsed) water outputs and vibration issues. Proper engineering is required to alleviate these issues such as a discharge dampener and slower pump rates.

MP-70R Water Pump

The Reverse Osmosis Process

Seawater ranges between 27,000 to 35,000 ppm total dissolved solids (TDS). The Red Sea is even higher at 40,000 to 45,000 ppm TDS. The reverse osmosis membrane has a pore size of about .001 microns, which is about 1/100,000th the diameter of a human hair. Under pressure, freshwater passes through the membrane while concentrated saltwater containing minerals and pollutants are flushed to waste or saved for further recycling and processing.

Brackish Water Membranes

The osmotic membrane allows water to pass through it at much higher rates than dissolved salts. Some desalination designs use electrostatically charged RO membranes to improve the separation of minerals and salts from the water. Desalination systems use multiple reverse osmosis membrane filters to increase the amount of purified product water produced per day. Each RO filter housing contains a spiral-wound semi-permeable membrane. The desalination process concentrates the mineral and salt ions around the membrane film during the desalination process. However, if the salts are concentrated beyond the allowable saturation level, solid mineral scale can form on the membrane. Anti-scalant is added as a requirement of RO process design to prevent damaging mineral scale from forming inside the RO system.

The reverse osmosis membranes used on desalination systems typically have a 99% or higher salt rejection rate with 45% or higher recovery rate. The lower recovery rate is maintained to reduce the chances of scale formation within the desalination process. More water is used to flush away scale-causing salts. RO membranes are the costliest consumable in the desalination process. Minimizing membrane damage and extending service life is a major cost-reducing goal. The trade-off between membrane replacement costs, down-time and maintenance is balanced with the lower recovery rate.

Post Treatment and Storage

At this stage the water is fresh but not biologically pure. The freshwater may be exposed to an ultra-violet disinfection system. When micro-organisms such as algae, fungi, bacteria and parasites are exposed to 254 nm UV radiation, it damages their DNA and they die. The strength of the UV unit is calculated on microwatts per second per square centimeter. In high-capacity desalination plants the water flow is divided between several UV units. This careful calculation ensures proper disinfection of the water as it moves past the UV lamps at the proper rate. The RO water may be blended with filtered groundwater to add back pH buffering and minerals associated with good tasting tap water. The water may also be treated with a disinfectant like chlorine or chloramine before being sent to city-wide water distribution system.

Polaris UVA-24B UV Reactor

Does desalination make sense?

A reverse osmosis desalination system is justifiable anywhere there is a shortage fresh water and a good source of available brackish or seawater. While many desalination plants have been constructed in dry environments and island coastal communities. But as viable freshwater sources become more scarce, both industry and municipalities are adopting RO-based desalination.

Leave a comment

You must be logged in to post a comment.